-

Jake MillerWir sind das Risiko mit inverters-vfd.com für den kritischen VFD-Ersatz in unserer Produktionslinie eingegangen. Das Produkt passte nicht nur perfekt, sondern war auch günstiger als unser bisheriger Lieferant. Seine Stabilität hat unsere häufigen Ausfallprobleme beseitigt. Ein hervorragendes Preis-Leistungs-Verhältnis und ein zuverlässiger Partner für Industriekomponenten.

Jake MillerWir sind das Risiko mit inverters-vfd.com für den kritischen VFD-Ersatz in unserer Produktionslinie eingegangen. Das Produkt passte nicht nur perfekt, sondern war auch günstiger als unser bisheriger Lieferant. Seine Stabilität hat unsere häufigen Ausfallprobleme beseitigt. Ein hervorragendes Preis-Leistungs-Verhältnis und ein zuverlässiger Partner für Industriekomponenten. -

Sarah ChenDas technische Team von inverters-vfd.com war von unschätzbarem Wert. Ich beschrieb unsere Anwendung für einen Servomotor, und sie empfahlen ein Modell mit überlegenem dynamischen Verhalten. Die Installation verlief reibungslos, und die Präzision hat unsere Zykluszeiten verbessert. Fachkundige Beratung und ein Hochleistungsprodukt!

Sarah ChenDas technische Team von inverters-vfd.com war von unschätzbarem Wert. Ich beschrieb unsere Anwendung für einen Servomotor, und sie empfahlen ein Modell mit überlegenem dynamischen Verhalten. Die Installation verlief reibungslos, und die Präzision hat unsere Zykluszeiten verbessert. Fachkundige Beratung und ein Hochleistungsprodukt! -

David "Big D" KowalskiUnsere Bestellung mehrerer SPS-Einheiten und HMIs wurde präzise ausgeführt und mit erstaunlicher Geschwindigkeit versandt. Seit der Integration ist die Kommunikation unseres Steuerungssystems robuster. Wir sind beeindruckt von der Logistik und der soliden Leistung dieser Komponenten. Ein rundum problemloses Erlebnis.

David "Big D" KowalskiUnsere Bestellung mehrerer SPS-Einheiten und HMIs wurde präzise ausgeführt und mit erstaunlicher Geschwindigkeit versandt. Seit der Integration ist die Kommunikation unseres Steuerungssystems robuster. Wir sind beeindruckt von der Logistik und der soliden Leistung dieser Komponenten. Ein rundum problemloses Erlebnis. -

Emily WhiteWir benötigten einen geräuscharmen Spindelmotor für eine empfindliche Testumgebung. Das von uns gekaufte Gerät arbeitet flüsterleise und hält ein konstantes Drehmoment. Die Qualität übertrifft einige bekannter Marken, die wir verwendet haben, zu einem Bruchteil der Kosten. Hervorragend für spezielle Anwendungen.

Emily WhiteWir benötigten einen geräuscharmen Spindelmotor für eine empfindliche Testumgebung. Das von uns gekaufte Gerät arbeitet flüsterleise und hält ein konstantes Drehmoment. Die Qualität übertrifft einige bekannter Marken, die wir verwendet haben, zu einem Bruchteil der Kosten. Hervorragend für spezielle Anwendungen.

Advanced Short Circuit Protection for Secure VFD System Operation

| Herkunftsort | CHINA |

|---|---|

| Markenname | COENG |

| Zertifizierung | CE |

| Modellnummer | HV300-12 |

| Dokument | HV300.docx |

| Min Bestellmenge | 1 |

| Verpackung Informationen | Holzkiste |

| Lieferzeit | 10-30 Arbeitstage |

| Zahlungsbedingungen | L/C, T/T, Western Union |

| Versorgungsmaterial-Fähigkeit | 20000SETS/YEAR |

Treten Sie mit mir für freie Proben und Kupons in Verbindung.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skypen: sales10@aixton.com

Wenn Sie irgendein Interesse haben, leisten wir 24-stündige Online-Hilfe.

x| Leistungsbereich | 0.4kW bis 500kW | Eingangsspannung Uin | 200V (-15%) ~ 240V (+10%) 1PH/3PH 380V (-15%) ~ 480V (+10%) 3PH 500V 500V (-15%) ~ 690V (+10%) 3PH |

|---|---|---|---|

| Eingangsfrequenz | 50 Hz/60 Hz ± 5% | Kommunikationsschnittstelle | RS485, RJ45 |

| Kommunikationsprotokoll | MODBUS RTU | Luftfeuchtigkeit | < 90% RH, keine Kondensation |

| Operations-Temperatur | -20°C~+40°C (Betrieb mit Abwärmung bei 40°C~55°C) | ||

| Hervorheben | VFD short circuit protection,secure vector frequency inverter,VFD system protection |

||

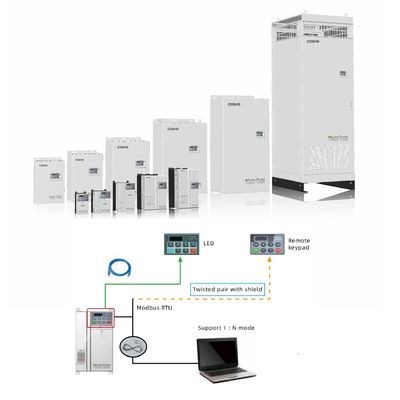

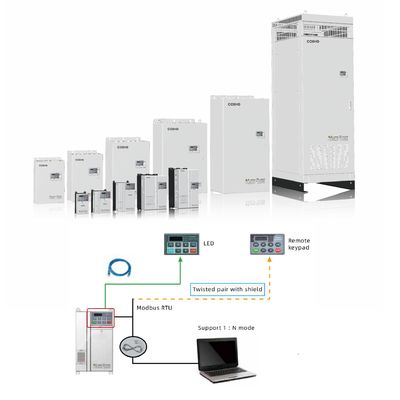

Vector Frequency Inverter Product Description

The HV300 Series inverter is a cutting-edge, multi-function universal vector frequency inverter, also known as a variable frequency drive (VFD) or AC drive. This recently developed inverter incorporates advanced open-loop and closed-loop vector control technology, allowing precise control of asynchronous motors.

Designed with a focus on software functionality, performance enhancement, and reliability, the HV300 inverter offers a more compact size without compromising expandability. It provides users with a wider range of communication capabilities, enabling seamless integration into various industrial systems.

With its user-friendly interface and intuitive controls, the HV300 inverter ensures simpler operation and configuration. Its comprehensive features and parameters can be easily accessed and adjusted to meet specific application requirements.

The HV300 Series inverter offers advanced functionality, enhanced performance, and increased reliability. It is a versatile solution for various industrial applications, providing precise control, efficient operation, and simplified integration into existing systems.

Variable Frequency Inverter VFD Product Technical Specification

| Specification | Value |

|---|---|

| Input Voltage | 200V (-15%) ~ 240V (+10%) 1PH/3PH; 380V (-15%) ~ 480V (+10%) 3PH 500V;500V (-15%) ~ 690V (+10%) 3PH |

| Input Frequency | 50Hz/60Hz±5% |

| Maximum Supply Imbalance | ≤3% |

| Output Voltage | 0V ~ Uin |

| Output Frequency | 0Hz ~ 300Hz |

| Power Range | 0.4kW ~ 500kW |

| Mounting Method | Cabinet installation, Through panel, surface mounting |

| Ingress Protection | IP20, IP21 (by adding optional device) |

| Torque Accuracy | ≤5% (OLVC) |

| Storage Temperature | -40 ℃~+70℃ |

| Starting Torque | 0.5Hz: 150% (OLVC), 1Hz: 150% (OLVC) |

Variable Frequency Inverter VFD Product Typical Application

Oilfield Pumping Unit:

- Location: Oilfield

- Power: 22kW

- Efficiency: Achieve significant power savings of over 30% while protecting the grid and equipment from overcurrent issues.

- Key Advantages: Versatile voltage range for seamless adaptation to demanding grid conditions; Smooth speed control with low starting current, ensuring minimal impact on the grid; Equipped with built-in EMC filter and standard-configured DC reactor, reducing radiation.

![]()

Steel Plant Roller:

- Location: Tianjin steel plant

- Power: 22kW, 30kW, 37kW, 45kW

- Performance: Ensures exceptional operational stability with a fault rate below 1%.

- Key Advantages: Designed to handle reciprocating acceleration and deceleration, providing reliable performance; Capable of supporting long-term continuous operation; Built to withstand high temperatures and meet stringent protection requirements in steel workshops; Facilitates integration into Profibus DP network.

![]()

Steel Plant Cold Saw:

- Location: Tangshan steel plant

- Power: 450kW

- Performance: Enables high overload operation, maintaining stable speed control to meet process demands.

- Key Advantages: Exceptional overload capacity for heavy-duty operations; Quick response and precise speed control, even at high speeds; Engineered to withstand high temperatures and fulfill rigorous protection requirements in steel workshops; Supports seamless integration into Profibus DP network.

![]()

1. FAQ for Italy

-

Q: Is the VFD suitable for Italian textile machinery?

A: Yes, high torque accuracy and frequency range support precise speed control. -

Q: How does it handle voltage sags in historical buildings?

A: Wide input tolerance and built-in protection ensure reliability. -

Q: Can it reduce energy costs for small workshops?

A: Definitely—the DC reactor and high efficiency cut energy waste. -

Q: Is the Profibus setup compatible with Italian industrial networks?

A: Yes, it supports standard PPO formats used in Italy. -

Q: What are the mounting options for compact spaces?

A: Cabinet, panel, or surface mounting available. -

Q: How does it perform in high-temperature summers?

A: Excellent heat dissipation and thermal protection ensure stable operation. -

Q: Can I use it with Italian-made motors?

A: Yes, it works with all standard three-phase motors. -

Q: What is the lead time for Sicily?

A: We ship within 5–7 business days across Italy. -

Q: How does the overcurrent reset function work?

A: It delays reset to prevent repeated tripping, improving system stability. -

Q: Is local training available?

A: Yes, we offer online and on-site training in Italian.

2. FAQ for Spain

-

Q: Can the VFD handle solar farm applications?

A: Yes, it is ideal for renewable energy systems with variable frequency inputs. -

Q: How does it perform in dry, dusty regions?

A: IP20 standard and optional IP21 provide adequate protection. -

Q: Is it easy to configure for irrigation systems?

A: Yes, the user-friendly interface and DIY logic simplify setup. -

Q: What is the harmonic distortion level?

A: Below 5% with the DC reactor, meeting Spanish grid codes. -

Q: Can it be used with Spanish automation protocols?

A: Profibus is widely accepted, and other protocols can be customized. -

Q: How reliable is the IGBT under frequent start-stop cycles?

A: Very reliable—thanks to real-time temperature monitoring. -

Q: What is the noise level during operation?

A: Low noise design, suitable for urban and residential areas. -

Q: Does it support regenerative braking?

A: Yes, for applications requiring frequent deceleration. -

Q: Are spare parts readily available in Spain?

A: Yes, we have a local distribution network. -

Q: Can I monitor performance via smartphone?

A: With optional communication modules, yes.

3. FAQ for Japan

-

Q: Is the VFD compatible with Japan’s 100V/200V dual voltage system?

A: Yes, it supports 200V–240V single/three-phase input. -

Q: How does it meet Japanese energy-saving standards?

A: High efficiency and power factor improvement help achieve Top Runner compliance. -

Q: Can it withstand seismic activity?

A: Robust construction and secure mounting options enhance earthquake resistance. -

Q: Is the Profibus interface common in Japan?

A: Yes, and it also supports CC-Link with customization. -

Q: How does it handle humid summers?

A: The PCB is coated for humidity protection, and thermal management is advanced. -

Q: What applications is it best for?

A: Robotics, HVAC, and precision manufacturing. -

Q: Is technical documentation available in Japanese?

A: Yes, all manuals and support are localized. -

Q: How does the DIY function benefit small batch production?

A: It allows rapid adaptation to changing production needs. -

Q: What is the delivery time for Tokyo?

A: Typically 3–5 business days. -

Q: Can it be used with Japanese servo drives?

A: Yes, with proper parameter setting.

4. FAQ for India

-

Q: How does the VFD handle frequent power cuts and voltage swings?

A: Wide input voltage range and built-in protection ensure uninterrupted operation. -

Q: Is it suitable for agricultural pump sets?

A: Yes, with high starting torque and robust design. -

Q: Can it reduce diesel generator dependency?

A: Absolutely—improved efficiency lowers generator load and fuel consumption. -

Q: How does it perform in dusty environments?

A: IP20 protection and optional filters are available. -

Q: Is local service support available?

A: Yes, we have service centers in major cities. -

Q: What is the cost of ownership?

A: Low—thanks to energy savings and minimal maintenance. -

Q: Can it be used in textile mills?

A: Yes, precise speed control is ideal for spinning and weaving. -

Q: How easy is installation for non-technical users?

A: Simple wiring and preset parameters make it easy. -

Q: Does it support three-phase motors commonly used in India?

A: Yes, fully compatible. -

Q: What is the warranty period?

A: Standard 2 years, extendable.